-

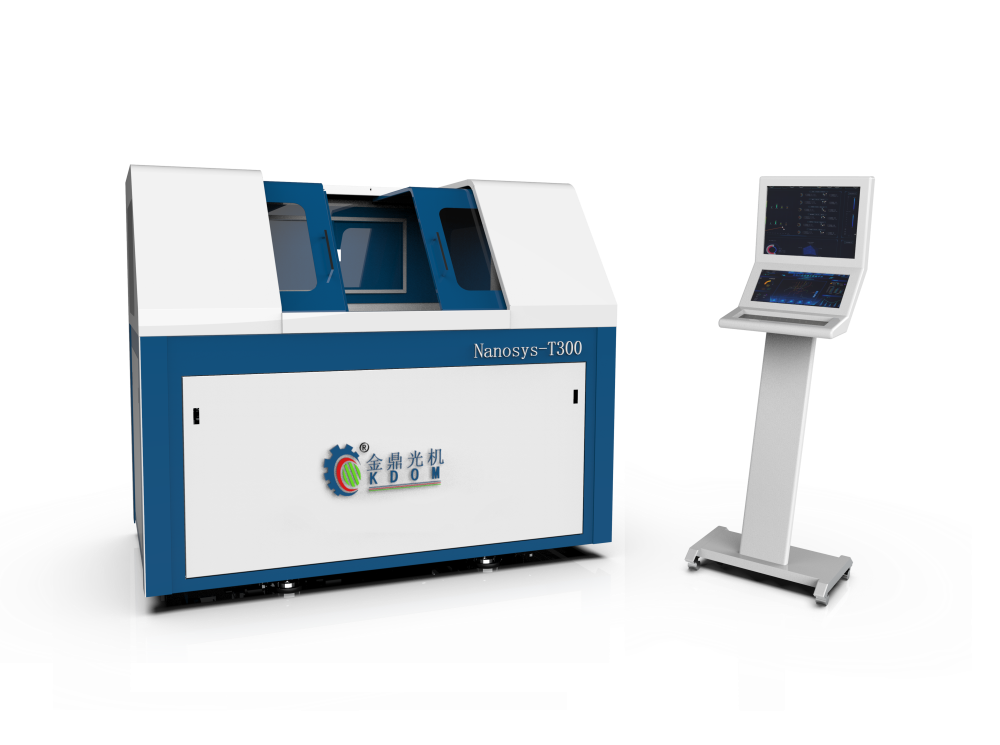

Ultra precision single point diamond lathe

Nanosys-T300

Equipment features: * This machine is an ultra-precision 3-axis CNC machine tool; Suitable for optical lens, infrared lens, precision mold core and other precision mechanical parts, the main application direction infrared lens processing, aluminum copper mirror processing, mold core processing, etc. * The equipment adopts natural granite structure, with excellent thermal stability and shock absorption ability; Automatic leveling air isolation system; The computer system is configured with 64-bit Windows7 Professional Edition; Control system based on Power UMac motion controller development control system; Programming resolution 0.01 nm (straight line) / 0.0000001 ° (rotation). * Surface accuracy (P-V) : 0.3µm / ⌀70mm; Surface roughness (Ra) :≤4nm. * This equipment is an ultra-precision 4-axis CNC machine tool; Applicable to thousands of free-form surfaces, cylinders, spheres, cones, Ultra-precision grinding of high gradient aspherical surface, gull wing aspherical surface and micro-structure characteristic optical elements; Grinding materials include: Ming steel, optical glass, quartz glass, ceramics, etc. * The equipment adopts natural granite structure, with excellent thermal stability and shock absorption ability; Automatic leveling air isolation system; The computer system is configured with 64-bit Windows7 Professional Edition; Control system base thousand PowerUMac motion controller development control system; Programming resolution 0.01 nm (straight line) / 0.0000001 ° (rotation); * Surface accuracy (P-V) : 0.3µm / 20mm, surface roughness (Ra) :≤5nm. * This equipment is an ultra-precision 4-axis CNC machine tool; Applicable to thousands of free-form surfaces, cylinders, spheres, cones, Ultra-precision grinding of high gradient aspherical surface, gull wing aspherical surface and micro-structure characteristic optical elements; Grinding materials include: Ming steel, optical glass, quartz glass, ceramics, etc. * The equipment adopts natural granite structure, with excellent thermal stability and shock absorption ability; Automatic leveling air isolation system; Computer system configuration 64-bit Windows7 Professional version; Control system base thousand PowerUMac motion controller development control system; Programming resolution 0.01 nm (straight line) / 0.0000001 ° (rotation); * Surface accuracy (P-V) : 0.3µm /⌀ 20mm, surface roughness (Ra) :≤5nm.

View More >

-

Ultra precision aspherical surface grinding lathe

Nanosys-G250

Equipment features: * This equipment is an ultra-precision 4-axis CNC machine tool; Applicable to thousands of free-form surfaces, cylinders, spheres, cones, Ultra-precision grinding of high gradient aspherical surface, gull wing aspherical surface and micro-structure characteristic optical elements; Grinding materials include: Ming steel, optical glass, quartz glass, ceramics, etc. * The equipment adopts natural granite structure, with excellent thermal stability and shock absorption ability; Automatic leveling air isolation system; The computer system is configured with 64-bit Windows7 Professional Edition; Control system base thousand PowerUMac motion controller development control system; Programming resolution 0.01 nm (straight line) / 0.0000001 ° (rotation); * Surface accuracy (P-V) : 0.3µm / 20mm, surface roughness (Ra) :≤5nm.

View More >

-

Ultra precision aspherical mold polishing lathe

KDMP-100

Equipment features: * This equipment is suitable for the precision surface of the 3-CD90mm round aspherical mold in diameter Polish. * Touch screen convenient operation interface, high-precision motion control system, can directly import the mold Surface data to realize automatic surface compensation processing. * High precision polishing for precision molds with rough surfaces.

View More >

-

Single Station Precision Glass Molding Machine

MD-315V

Equipment features: * This equipment is suitable for precision optical lens molding; In a nitrogen or vacuum atmosphere, the glass is heated to a deformed state while applying pressure; Moulds are used to press the glass into the desired shape. * The equipment uses infrared heating device, can quickly heat the mold and maintain its temperature uniformity, can separately control the temperature of the upper and lower mold; Suitable for metal mold and ceramic mold, can be a mold one hole molding, can also be a mold multi-hole molding; Accurate position control via encoder; Accurate pressure control via pressure sensor; The multistage vacuum system can reach a vacuum degree of 0.6Pa, and can be formed under vacuum conditions to achieve glass molding on special surfaces such as flat and array surfaces. * molding process: in the pre - form closed molding chamber, vacuum, nitrogen filling (do not need to fill nitrogen when the vacuum forming), add heat to molding temperature, extrusion forming, with nitrogen cooling, open molding chamber, remove the lens after cooling to the set temperature.

View More >

-

spheric precision molding machine

MD17-36

This device is suitable for the hot pressing molding of large quantities of high-precision aspheric lenses. The raw materials are placed in the mold and then introduced into the molding chamber for sequential heating, molding, cooling, and other treatments, after which they are discharged from the molding chamber.

View More >

-

Molding machine automatic loading robotic arm

MD17-36-F-V

This robotic arm is designed to be used in conjunction with an aspheric molding machine, enabling automation of the feeding and discharging processes, as well as intelligent monitoring and alarm handling for mold damage, glass residue, and defective lenses.

View More >

Wechat

Wechat

Tiktok

Tiktok

Blog

Blog